For any business engaged in welding, whether small-scale fabrication or large industrial production, understanding and complying with welding fume extraction regulations in New Zealand is essential. Not only does it safeguard the health and wellbeing of your staff, but it also protects your business from costly penalties and reputational damage. At Egmont Air, we’ve seen many businesses grapple with outdated fume extraction systems. Either falling short of today’s stricter compliance standards or unable to cope with the increased output from newer, high-performance welding equipment, and we want to ensure your business stays up to standard.

In New Zealand, the regulations around welding fumes are becoming more stringent in line with growing global awareness of the health risks associated with airborne contaminants. Welding fumes are now officially classified as carcinogenic, and WorkSafe NZ has made it clear that businesses must take appropriate steps to manage and control exposure.

In this article, we’ll take a closer look at the current welding fume extraction regulations in New Zealand and what they mean for your business in practical terms. We’ll explore the legal responsibilities employers have under WorkSafe NZ guidelines and the Health and Safety at Work Act, and explain the consequences of falling short. Just as importantly, we’ll outline how Egmont Air can support you with reliable, tailored solutions that not only help you meet regulatory requirements but also improve overall workplace safety and efficiency. Whether you’re upgrading existing systems or starting from scratch, we’ll show you how to take a proactive approach to compliance and protect your people in the process.

What Are the Current Welding Fume Regulations in New Zealand?

WorkSafe NZ has outlined clear expectations around the control of airborne contaminants. All welding fumes, regardless of the material, are now treated as hazardous. This includes mild steel, which was once seen as relatively low risk.

Under the Health and Safety at Work Act 2015 (HSWA), employers must identify all workplace hazards, assess the associated risks, and implement effective controls. For welding, this means evaluating the level of exposure and putting in place appropriate engineering controls, such as local exhaust ventilation (LEV) or fume extraction systems. Where elimination of the hazard is not practical, minimisation must follow.

The use of on-tool or local fume extraction systems is widely encouraged, along with proper ventilation, regular monitoring, and ongoing maintenance of all equipment. Employers are also responsible for providing training to ensure workers use these systems correctly and consistently.

It’s important to remember that WorkSafe’s expectations are not static. Regulations around welding fume exposure are continuously evolving, with updates often driven by emerging scientific research and changes to international best practices. For example, the reclassification of welding fumes as a known carcinogen has already prompted a significant tightening of standards, and further revisions are likely as our understanding of occupational health risks deepens. Staying ahead of these changes isn’t just good practice, it’s essential for protecting your business, your team, and avoiding costly disruptions. At Egmont Air, we specialise in helping businesses navigate this shifting landscape. Our team stays up to date with the latest regulatory developments and translates them into practical, achievable solutions that keep your business both compliant and future-ready.

The Real Risks of Non-Compliance

The consequences of falling short of welding fume regulations are twofold: serious health risks for your team and significant liabilities for your business.

From a legal standpoint, WorkSafe has the authority to impose serious penalties on businesses that fail to manage welding fume exposure adequately. These penalties can reach well over $100,000, depending on the nature of the breach and the size of the business. Beyond fines, there’s also the risk of being ordered to halt operations until corrective actions are taken.

But the more pressing concern is the risk to your team. Welding fumes are a complex mixture of airborne particles and gases, generated when metal is heated above its boiling point and condenses into fine particulates. These fumes often contain harmful substances such as metal oxides, silicates, fluorides, and even toxic gases like ozone and nitrogen oxides, depending on the welding process and materials used. Long-term inhalation of these substances can lead to a range of serious health conditions, including occupational asthma, chronic obstructive pulmonary disease (COPD), and neurological damage caused by exposure to manganese. More so, with the International Agency for Research on Cancer (IARC) having classified all welding fumes as Group 1 carcinogens, means there is sufficient evidence they cause cancer in humans.

Short-term exposure is not without consequence either. Workers can experience acute symptoms such as dizziness, headaches, nausea, irritation of the eyes and throat, or develop a condition known as metal fume fever. This flu-like illness results from inhaling freshly formed metal oxide fumes and can lead to chills, fever, and muscle aches. Over time, repeated acute exposures can have cumulative effects, leading to more serious long-term damage.

Providing a clean-air workspace isn’t just about meeting your obligations, it’s about protecting the people who keep your business running. That’s where effective welding air filtration systems come into play.

How Egmont Air Supports Compliance and Workplace Safety

Egmont Air has been helping New Zealand businesses improve their air quality and meet health and safety standards for over 25 years. Our focus is on practical, reliable fume extraction systems that deliver long-term value while helping you comply with evolving regulations.

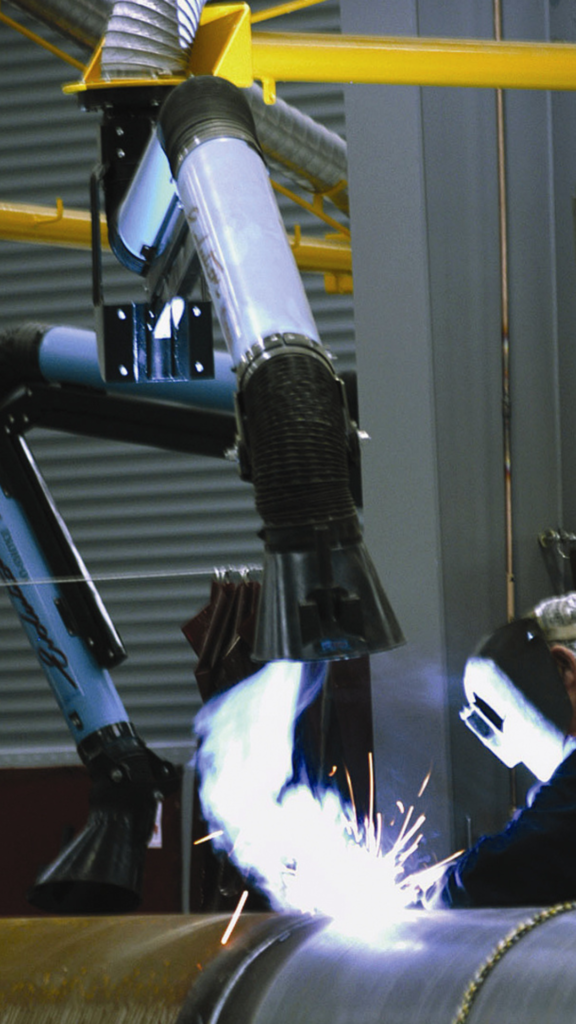

We begin by carrying out a thorough site assessment, looking at your facility layout, welding processes, and specific risks. This ensures that any solution we recommend is tailored to your unique setup. Whether you need a portable welding fume extractor for flexibility across different work zones, or a centralised extraction system to manage multiple welding bays, we provide systems that are effective, durable, and easy to maintain.

One common challenge for businesses is finding the balance between performance and cost. Egmont Air addresses this by walking you through a wide range of options, including portable units, wall-mounted extraction arms, and fully ducted systems with advanced filtration. All systems are designed with New Zealand conditions in mind and backed by expert local support.

Installation is handled by our experienced team, ensuring systems are configured correctly for maximum performance. We also provide training so your staff can operate and maintain the equipment effectively.

Ongoing maintenance is another crucial factor in compliance. A fume extraction system is only as effective as its filters and airflow. Egmont Air offers service packages that include filter checks, airflow testing, and compliance documentation to keep your workplace audit-ready at all times.

Proven Results Across NZ Workshops

Egmont Air’s expertise isn’t just theoretical, it’s been proven in workplaces across the country.

One proven example of effective fume extraction in action comes from a local Auckland-based manufacturer who partnered with Egmont Air to improve air quality in their welding workshop. The business was concerned about the growing health risks associated with welding fumes and wanted to ensure full compliance with WorkSafe regulations. After a site assessment, Egmont Air designed and installed a series of wall-mounted welding fume extractor arms, tailored to suit each welding bay. These arms allowed operators to capture fumes at the source, before they dispersed into the wider workshop, dramatically improving air quality. As a result, the company not only protected the health of its welders but also created a cleaner, more professional working environment that increased productivity. Their proactive approach to fume control positioned them ahead of regulatory requirements and reinforced their commitment to worker safety.

This highlights how compliance and productivity can go hand in hand, when the right systems are in place.

Getting Started: What to Do Next

If you’re unsure whether your workshop or factory meets the latest welding fume extraction regulations, now is the time to act. Compliance isn’t a one-off checklist, it’s a constantly ongoing responsibility.

Egmont Air makes it easy to take the next step. We begin with a site visit, providing a no-obligation assessment of your current setup. From there, we develop a practical solution that suits your space, staff, and budget. Once installed, our systems are supported by ongoing service options that keep everything running smoothly and ensure you’re meeting your legal requirements.

The process is simple, but the impact is significant. Improved air quality leads to better health outcomes, fewer sick days, higher productivity, and peace of mind for you and your team.

Why Choose Egmont Air?

New Zealand businesses trust Egmont Air because we offer more than just equipment. We deliver results. Our expertise in industrial fume extraction systems, combined with a hands-on approach to customer support, ensures you’re not only compliant but operating at your best.

Our systems are designed for performance and longevity, backed by a team that understands both the technical and regulatory landscape. We pride ourselves on delivering value without compromise, helping businesses across the country protect their people and meet their responsibilities.

Final Thoughts

Welding fume extraction regulations in New Zealand are tightening for good reason. The evidence is clear: airborne contaminants pose a serious threat to worker health. The cost of inaction is high, but the solution doesn’t have to be complicated.

With Egmont Air, compliance becomes straightforward. We work with you to understand your needs, provide tailored solutions, and offer ongoing support to keep your systems effective and your people safe.

If you’re ready to improve air quality and meet your obligations, contact Egmont Air today for a free assessment. We’ll help you build a cleaner, safer, and more compliant workplace.