When you’ve been crafting quality kitchens and joinery for nearly four decades, you understand that attention to detail makes all the difference. Advanced Joinery, Canterbury’s multi-award winning joinery company, recently made a significant investment in their most valuable assets – their people – by upgrading their industrial dust extraction system with Egmont Air. The Challenge: Outgrowing Their Space Darrin Dudson, Managing Director of Advanced Joinery, faced a familiar challenge for successful businesses: growth. “We just needed more space, more capacity,”…

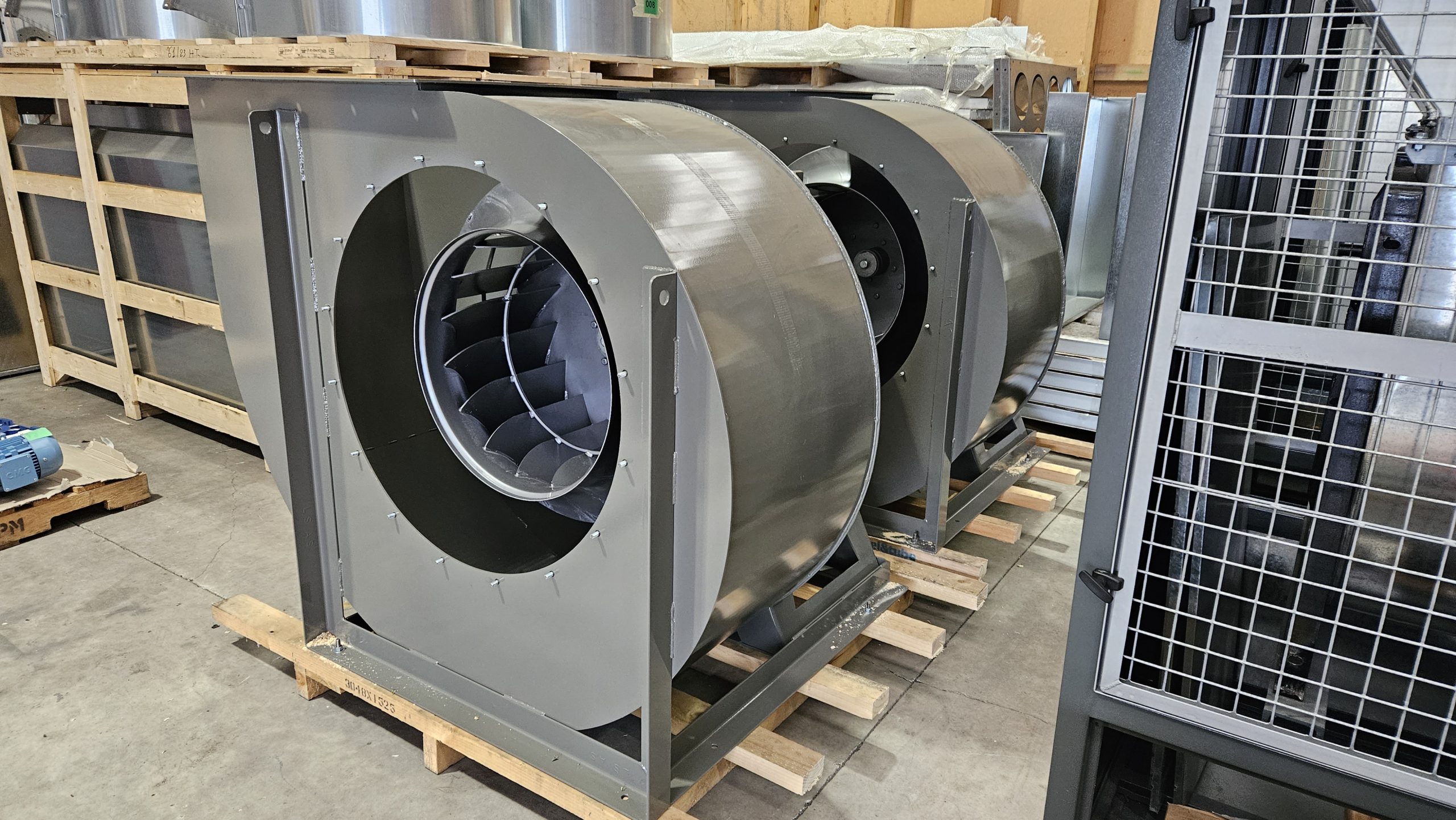

Advanced Joinery Have Upgraded Their Workshop with Industrial Dust Extraction