The right local exhaust ventilation (LEV) system for your workshop depends on three key factors: the type of work you do, the contaminants you need to control, and compliance requirements under New Zealand health and safety regulations. Welding, for example, creates hazardous fumes that must be captured at the source to protect workers and meet WorkSafe NZ standards. An effective LEV system removes these fumes before they spread, keeping your team safe and your business compliant.

In this guide, we’ll compare the main options available for welding fume extraction in New Zealand workshops, outline the regulations you need to know, and explain how to select the best LEV solution for your specific environment.

Why Welding Fume Control Matters

Welding fumes contain a mixture of metallic particles and gases, some of which are highly toxic. Long-term exposure can lead to serious respiratory issues, neurological effects, and even cancer. In New Zealand, WorkSafe welding fume extraction regulations make it clear that employers must minimise these risks through engineering controls like LEV. These regulations require employers to provide effective control measures, monitor exposure levels, and maintain equipment.

International standards, such as local exhaust ventilation OSHA guidelines, also stress the importance of keeping exposure below legal limits. Compliance is not just about ticking boxes – it’s about protecting your team. OSHA’s local exhaust ventilation for welding requirements also provide detailed guidance on airflow rates, system design, and inspection processes. For Kiwi businesses working with international clients or standards, it’s useful to be familiar with these requirements too.

Types of Local Exhaust Ventilation

There are several types of local exhaust ventilation systems available to provide respiratory protection, each suited to different workshop setups:

- Welding fume extractor – a portable or fixed unit designed to capture and filter fumes.

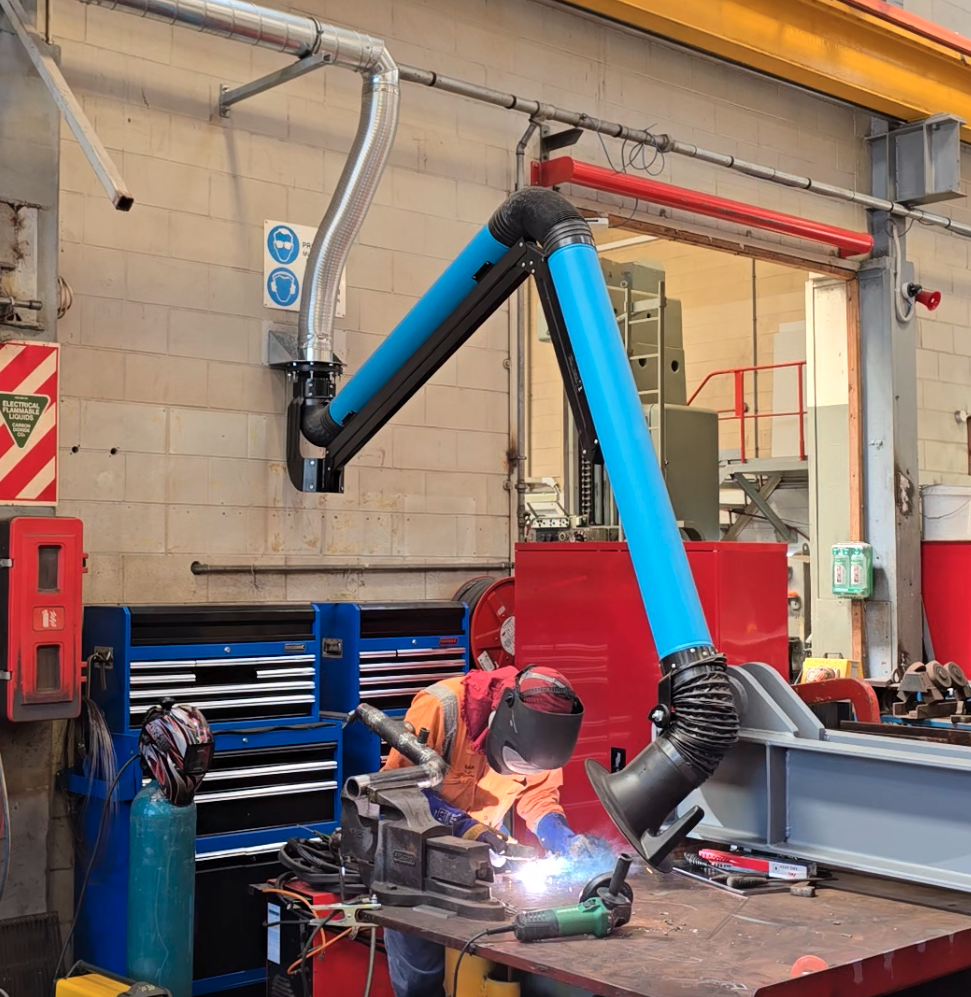

- Welding fume extractor arm – a flexible, adjustable arm that can be positioned close to the weld for effective fume capture, to help avoid exposure to welding fumes.

- On-torch welding extraction – integrated into the welding torch, this system extracts fumes directly at the point of generation, ensuring there is no contaminated air. An excellent solution for use in confined spaces as it removes contaminants at the source.

- Welding fume collector – often larger, centralised units that filter and collect welding fumes from multiple workstations.

- Local exhaust ventilation hood – this capturing hood captures fumes at a distance, often used where other methods are impractical.

Note: Push-Pull Ventilation and other General Ventilation systems may provide air-exchange and prevent accumulation of fumes in the workshop, but they do not provide Local Exhaust Ventilation and therefore are excluded from this article. They do not protect the worker or other employees working in the same vicinity.

When selecting an option, it’s important to consider how the equipment fits into your existing local exhaust ventilation design, as well as the mobility and efficiency needed in your workshop. Below is a framework for how our team calculates the right LEV solution for you

How do you calculate the right airflow for a Local Exhaust Ventilation system?Our team calculates it using the Local Exhaust Ventilation (LEV) formula, which determines the airflow required to effectively capture welding fumes at the source. We apply this formula to every project to ensure your system is powerful enough to protect workers while remaining energy-efficient and compliant with New Zealand safety standards. The Local Exhaust Ventilation Calculation Formula The basic formula is: Q=V×AQ = V \times AQ=V×A Where:

Example: Q=1.0×0.2=0.2 m³/sQ = 1.0 \times 0.2 = 0.2 \, \text{m³/s}Q=1.0×0.2=0.2m³/s That means your system needs to deliver at least 0.2 m³/s (≈ 425 CFM) at the hood face. This calculation is critical to ensure fumes are pulled into the local exhaust ventilation system, rather than drifting into the welder’s breathing zone. |

The Cost of Local Exhaust Ventilation

Local exhaust ventilation cost can vary widely depending on the type of system installed, the size of the workshop, and the complexity of the ducting or extraction design. While upfront costs can seem significant, it’s important to weigh them against compliance with WorkSafe welding requirements., reduced worker health risks, and improved productivity through a cleaner, safer environment. Ultimately, investing in the right LEV system saves money in the long run.

Weighing up these considerations played a key role in Titan Marine’s decision to reach out to us for a ‘capture at source’ solution. We installed an Evolution Extraction Arm connected to a centralised extraction system, and Ram Parshu, Fabrication Supervisor, was very satisfied with the outcome.

“We’re very pleased with the way Egmont Air came in, did all the calculations and worked out the layout of the workshop, and then took all of our feedback and how or what process we were doing, what sort of welding process and all that. Then they went back and did their homework and came back with a perfect result.”

You can read more about our LEV solution for this project here.

Choosing the Right LEV for Your Workshop

Selecting the right system means balancing effectiveness, compliance, and cost. For our clients we consider these parameters before designing a solution:

- The processes you use (MIG, TIG, stick welding, etc.).

- The layout of your workshop.

- Whether mobility is required (portable vs fixed systems).

- Budget for installation and ongoing maintenance.

When we partnered with Betteridge Engineering, we looked closely at their workshop layout, existing processes, and budget before deciding on the right solution. We installed an Egmont Air LEV welding fume extraction system, and the results were immediate. Betteridge’s lead welder, Maeli, had previously faced serious health issues that made welding for long periods difficult. With the new system in place, he’s noticed a huge difference: ‘I used to have a lot of health issues which impacted my welding, but with the new Egmont Air system I can weld all day!’”

For New Zealand workshops, choosing the right LEV system isn’t just about compliance – it’s about creating a safe, productive space for your team. From welding fume extractor arms to torch welding extraction, the right system, correctly calculated and maintained, will keep your workers safe from harmful fumes.

Investing in a well-designed local exhaust ventilation system means peace of mind for both employers and employees . Give us a call, and let’s get a solution sorted for you.