Welding Fume System – Case Study

Egmont Air, industry leaders in ‘dust & fume extraction’ recently designed, supplied and installed a new welding fume system for Trialcom.

Trailcom, a renowned supplier of trailer parts, required an extraction system that was versatile for their application of welding axle assemblies. Naturally most of the welding is done for the hubs at each end of the axle.

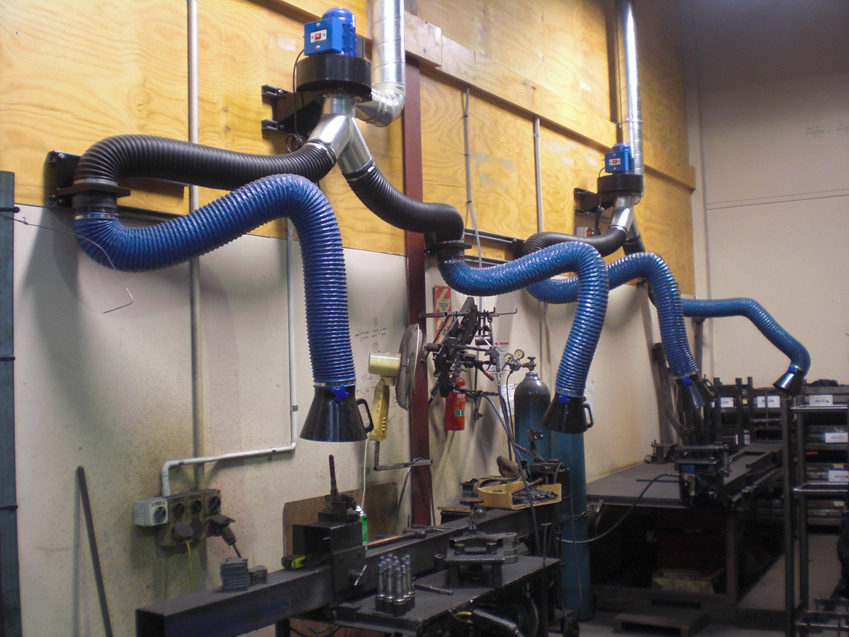

Egmont Air produced a double-hood extraction system that utilises two articulating extraction arms that can be strategically placed at each end of the axle to capture the fumes. In this way the fumes are captured as they are created, before they reach the operators breathing zone or spread throughout the working environment.

Mr Ken from Trialcom reports great success with the Egmont Air system and comments the ‘fume complaints have now stopped’. Trialcom place a large focus on Health and Safety and the Egmont Air system protects the welding operators from potential welding fume disease.

“Welding without adequate ventilation is dangerous” comments Mr Prestidge from Egmont Air, “Symptoms of a sore throat, dry cough, bleeding nose, headaches, breathlessness, nausea, sweating, chills and pneumonia are all signs that a correctly designed fume extraction system is urgently overdue”

Egmont Air, specialists in dust & fume extraction, offer a huge range of solutions for extracting welding fumes. “Increased productivity, employee wellbeing, reduction in absenteeism and staff turnover are direct benefits we have seen from installing an Egmont Air extraction system.”

“Our systems are designed to complement the work engineers do, so that productivity increases because of the improved and safer working conditions for welders” Mr Prestidge explains, ‘Job satisfaction’ and care of employees is seen as a major contribution to retaining staff and creating loyalty between workshop employees and management.”

A case study that reinforces the message involves a 54 year old welder who had never smoked but developed emphysema. Emphysema does not occur without an environmental cause (usually smoking) except in people with a genetic abnormality, which this man did not have. Lack of any other factors implicated welding fumes as the major cause of his disability. He had been welding for 30 years using a variety of processes and materials – however despite this mans history, he was unable to receive compensation.

Egmont Air Fume extraction systems are designed to suit welding bays, general engineering or maintenance workshop scenarios. Options are available for special processes such as robot welders, plasma fumes, grinding, and dust applications.

For a free brochure and more information contact Egmont Air on 0800 781 200